Have you ever taken interest in a supply chain project? If yes, you must have studied about the moving of stuff from one place to the next. Of course, engineering is a strong part of the project, there’s no running away from the transportation of materials from one location to the next. Every business owner has to struggle with transportation, handling of material, support, testing, and documentation. In most cases, human errors often get a lot of people in trouble. In some cases, they can cause massive losses to everyone around. However, if a company has a top-notch material handling system, nobody will have to worry about such issues. Before we dig deep into the crux of this discussion, it is essential to introduce the concept of a material handling system.

What is an Integrated Material Handling System?

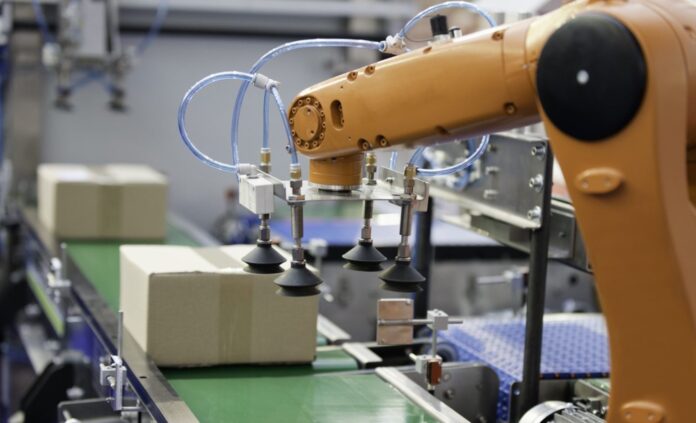

In simple words, an integrated material handling system smoothens the process of handling equipment. Most of the work is automated but you will also find people physically involved in carrying stuff. This process is broadly divided into 3 categories, cohesion, coordination, and connectivity. When you invest in an integrated handling system from a provider like Mainway Handling, every task is taken care of by the computer system. the workflow makes sure, the material is handled in the correct way and taken to the right location without any issue.

Benefits of Integrated Material Handling System

- Better Customer Service

There’s no running away from the fact that customer service is paramount in today’s time. if your customers aren’t happy, it will be hard for you to retain them in the long run. when the process is in the hands of an integrated system, the chances of human error are zero and the tasks are completed on time. This means the distributors of the product can receive the latter earlier than expected. As soon as they recover them, the customers will eventually get everything on time and be happy.

- Short Delivery Times

If the material is handled through a manual process, not only will it take a lot of time but the chances of delays will be very high. The integrated system has a designed workflow through which the material has to sift. This way, the chances of long delivery times are eventually reduced. However, for everything to navigate in the right direction, it is crucial that manual work is completed on time.

- Short Budget

Although it might seem daunting investing in an integrated material handling system can save a lot of money in the long run. every business owner aims to earn maximum profit with the investment of little capital. This goal is brought to life with the integrated material handling system. Thus, a business can save money and earn more in a short time.

- Better Inventory Management

No wonder, inventory management is a major issue in several companies across the globe. In severe cases, the stuff in the warehouse can get lost or even broken. However, when an integrated system is here to help, every business can avail of the benefit of better inventory management. Not to forget, inventory management is essential, otherwise, a typical business will have to spend a lot of money.

- Time-Saving

Last but not the least, time-saving is the most essential benefit of this concept. In today’s world, it is important for every business to make the most out of their time. As the world is moving towards the digital age, time-saving has emerged as a technical consequence. So with the integrated material handling system, since machines are performing most of the tasks, one can save a lot of time.